Production line automation:

Project Scope:

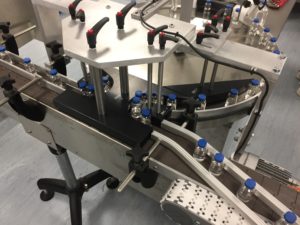

- Design new layout of packaging line

- Manufacture change parts to suit a range of product sizes

- Manufacture of bespoke feeding systems to control flow of products on line

- Manufacture rotary tables with feeding systems to allow for continuous flow of production

- Install new conveyors with new control systems

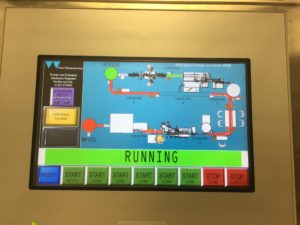

- Install central HMI and PLC to operate the line from one central location

- Run test and validate the entire line to Pharmaceutical validation protocols

Location: South of England

Customer: Pharmaceutical

Outcome: After the production line was automated the customer was able to double the amount of production in one day.